| Box Style | As Mention Above |

|---|---|

| Dimension (L + W + H) | All Custom Sizes & Shapes |

| Minimum Run ( For Boxes and Mylar Bags) | 100 Boxes - 1000 Mylar Bags ( 500 each design) |

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

| Printing | No Printing, CMYK, CMYK + 1 PMS color, CMYK + 2 PMS colors |

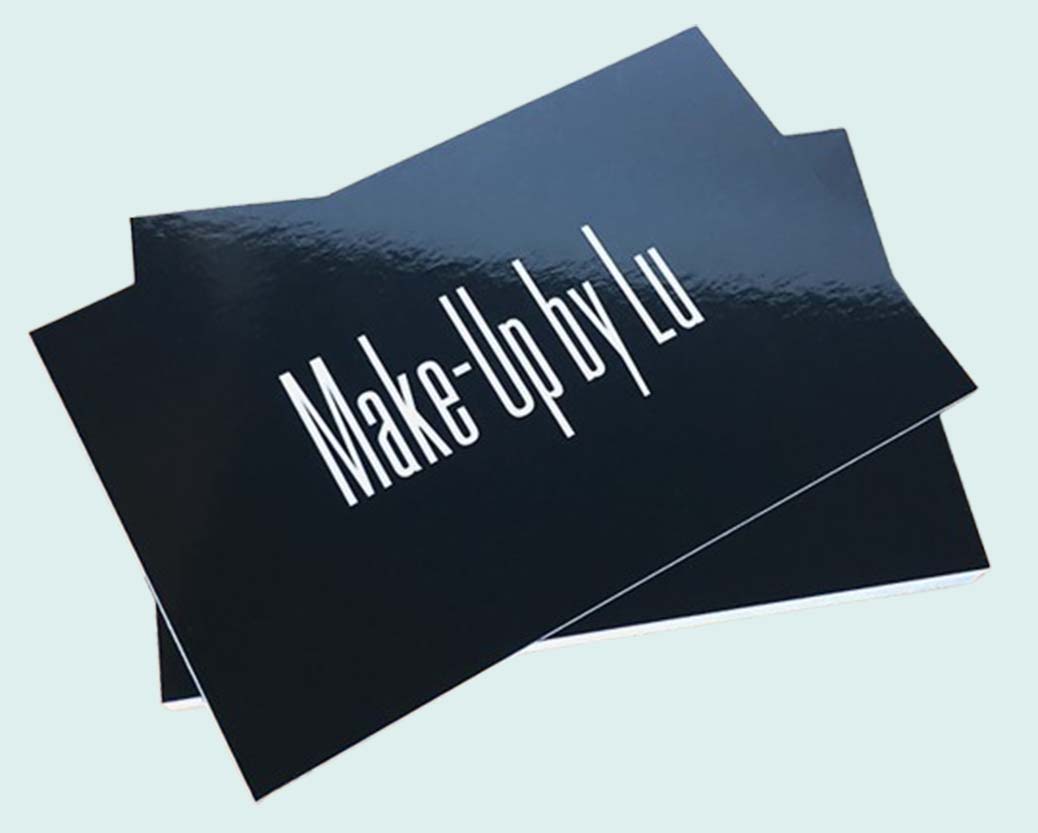

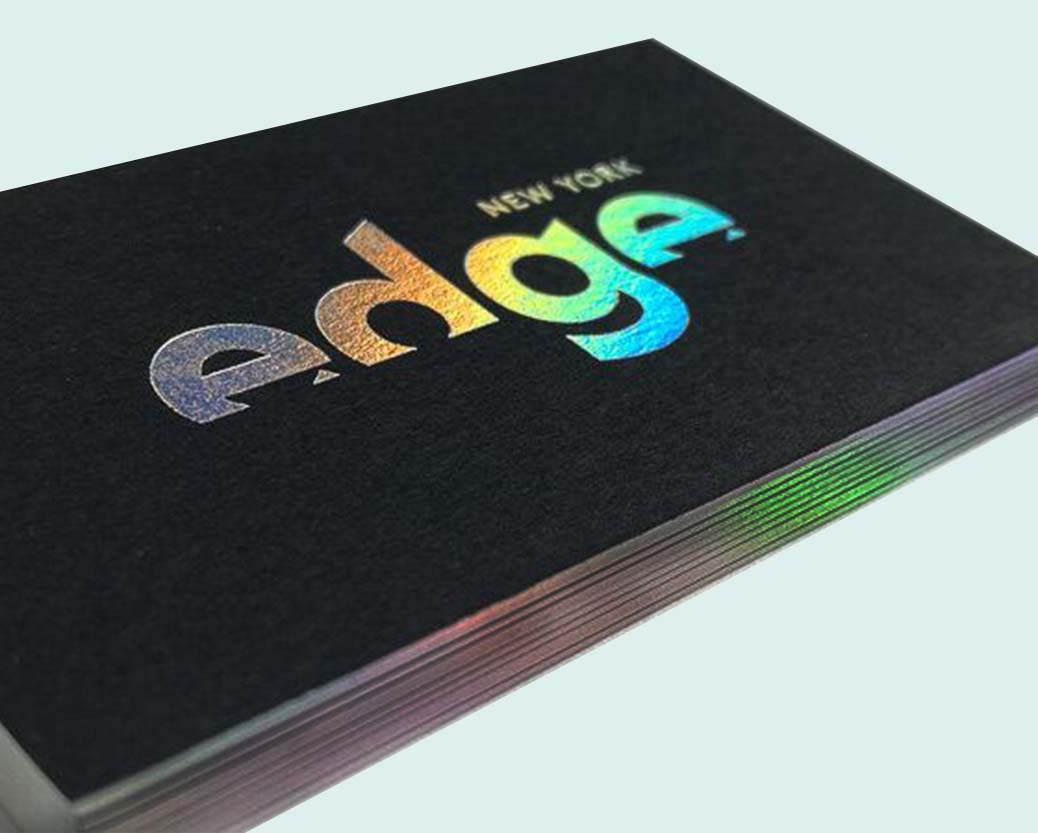

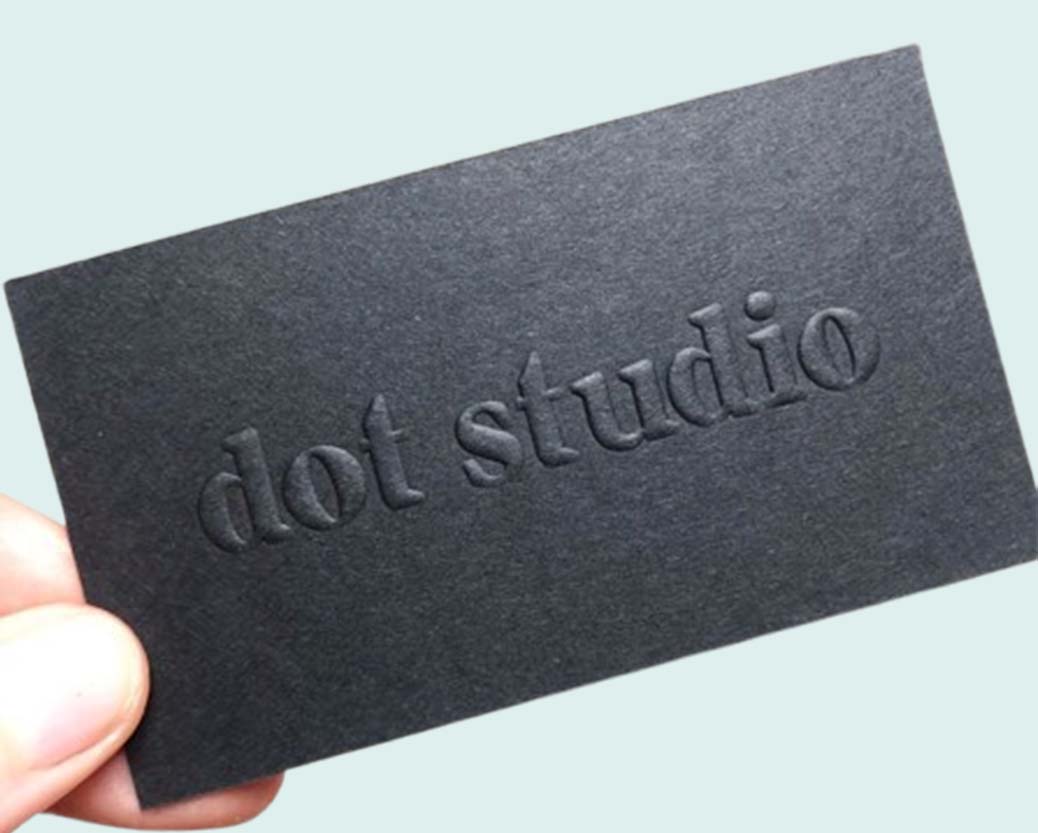

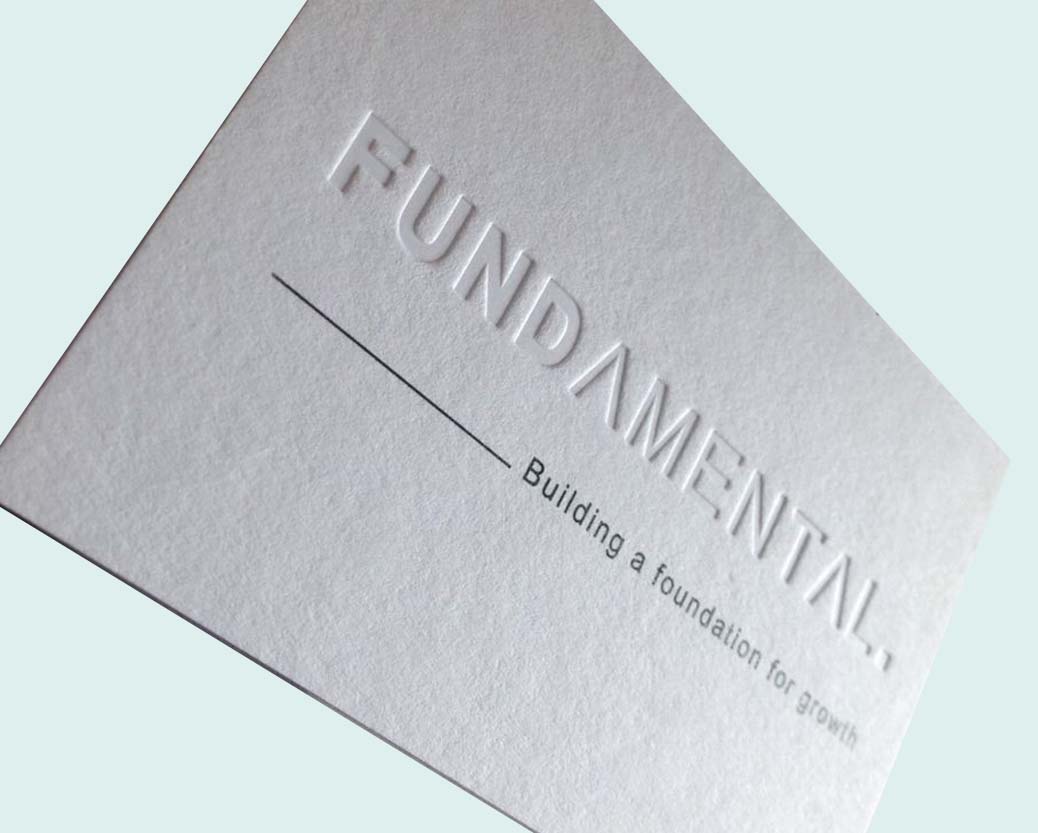

| Finishing | Gloss Lamination, Matte Lamination, Gloss AQ, Gloss UV, Matte UV, Spot UV, Embossing, Foiling |

| Included Options | Die Cutting, Gluing, Scored,Perforation |

| Additional Options | Eco-Friendly, Recycled Boxes, Biodegradable |

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) |

| Turnaround | 7 - 8 Business Days |

| Shipping | FLAT Position |

Corrugated E Flute Boxes

Using Corrugated E Flute Boxes is an excellent way to take your packaging to the next level. They are perfect for shipping, storage, and displaying your products professionally and attractively. Corrugated E Flute Boxes Wholesale options are available for bulk orders, making them a great solution for businesses looking for cost-effective solutions. In addition, innovative printing techniques have allowed for even greater customization. Through printing, you can create vivid designs and branding elements that will make your Corrugated E Flute Boxes stand out. Read on to learn more about the exciting possibilities available through printing for Corrugated E Flute Boxes.

Understanding E Flute Boxes and Their Benefits

Corrugated E Flute Boxes are a popular choice for packaging due to their numerous benefits. These boxes are made from a corrugated material consisting of flat inner and fluted outer layers. The "E" in E Flute refers to the thickness of the fluting, which is about 1/16th of an inch. This makes E Flute Boxes thinner and more lightweight than other corrugated boxes.

One of the major benefits of corrugated cube boxes is their strength and durability. Despite their thinness, they provide excellent product protection during shipping and storage. The fluting in the boxes acts as a cushion, absorbing shocks and impacts to prevent damage.

Conventional Printing Techniques for E Flute Boxes

Conventional printing techniques have been used for years to enhance the appearance of packaging, including Corrugated E Flute Boxes. These techniques provide reliable and cost-effective options for customizing your packaging and making it more visually appealing.

One common technique is offset printing, which uses ink to transfer images onto the E Flute Boxes. This method offers high-quality results and can reproduce complex designs and gradients accurately. It is suitable for larger print runs and provides excellent color accuracy.

Another popular conventional printing technique is flexographic printing. This method utilizes flexible rubber plates to apply ink onto the Corrugated E Flute Packaging. This versatile technique allows for vibrant and bold colors, making your packaging stand out on the shelves. Flexographic printing is a great option for shorter print runs and can be cost-effective for businesses with budget constraints.

Digital Printing for High Quality Graphics

One of the advantages of digital printing is its ability to reproduce vibrant and bold colors. This technique uses a digital file to directly transfer the desired design onto the E Flute Boxes, resulting in precise and accurate color representation. Whether you want to showcase your brand's logo or create eye-catching graphics, digital printing can bring your vision to life.Furthermore, digital printing offers exceptional flexibility and customization options. You can easily modify and adjust your designs without additional setup costs, making it perfect for small print runs or frequent design changes. This flexibility allows you to experiment with different graphics and branding elements, ensuring that your Corrugated E Flute Boxes are always up-to-date and visually appealing.

Flexographic Printing for Vibrant Colors and Customization

Flexographic printing is a versatile and popular printing technique for Corrugated E Flute Boxes that offers vibrant colors and customization options. This technique uses flexible rubber plates to apply ink onto the packaging, resulting in eye-catching and vivid designs.

One of the main advantages of flexographic printing is its ability to produce vibrant and bold colors. The ink used in flexographic printing is specially formulated to create bright and saturated hues, making your packaging stand out on store shelves. Whether you want to showcase your brand's logo or create striking graphics, flexographic printing can help you achieve the desired visual impact.

Litho Labeling for Photorealistic Images and Branding

Litho labeling is a printing technique that allows for the creating of photorealistic images and branding elements on Corrugated E Flute Boxes. This technique is perfect for businesses looking to make a visual impact and create packaging that truly stands out.

You can achieve highly detailed and lifelike images on your E Flute Boxes with litho labeling. Whether you want to showcase product photographs or create intricate illustrations, this printing method can bring your vision to life. The level of detail and clarity that litho labeling offers is truly impressive, allowing you to create packaging that captures attention and leaves a lasting impression on consumers.

Embossing, Debossing, and Foil Stamping for Textured Effects

Embossing, debossing, and foil stamping are three exciting printing techniques that can add textured effects to your Corrugated E Flute Boxes, taking your packaging to a new level.

Embossing involves creating a raised design or pattern on the box's surface. This technique adds depth and dimension to your packaging, making it visually interesting and appealing to touch. It can be used to highlight important branding elements or create unique textures that enhance the overall aesthetic of your boxes.

These textured effects enhance the visual appeal of your packaging and create a unique sensory experience for consumers. They make your boxes stand out and leave a lasting impression.

Choosing the Right Printing Technique for Your E Flute Box

When choosing the right printing technique for your Corrugated E Flute Box, it's essential to consider your specific needs and goals. Each printing technique offers unique advantages and can create different visual effects on your packaging.

If you're looking for high-quality graphics and vibrant colors, digital printing is an excellent choice. It allows for crisp and detailed images precise color representation, and offers flexibility in design customization. Digital printing is perfect for businesses that frequently change designs or require smaller print runs.

On the other hand, if you want vibrant colors and customization options, flexographic printing is a versatile technique. It uses flexible rubber plates to apply ink onto the packaging, creating eye-catching and vivid designs. Flexographic printing is suitable for large and small print runs, making it cost-effective for businesses of all sizes.

If you're aiming for photorealistic images and branding elements, litho labeling is the way to go. This technique provides highly detailed and lifelike images on your E Flute Boxes. It is ideal for businesses that want to create packaging that truly stands out and captures attention.

I love my boxes from customer boxes zone!!! Daniel has kept up on my interests and offered me much help. He made sure that all my specific needs were met and guided me along the way. My business is going to another level now. Thank you so much Daniel! You deserve ten stars if I could!